Enhance Project Efficiency with RainierGPR Concrete Scanning Services

Wiki Article

Exploring the Midst: A Comprehensive Overview to Concrete Scanning and Its Diverse Applications

In the world of construction and framework advancement, the thorough procedure of concrete scanning holds a critical duty in making sure the architectural honesty and safety of jobs. As technology continues to develop, the applications of concrete scanning have actually increased far past simple surface-level analyses.Relevance of Concrete Scanning

Recognizing the significance of concrete scanning is vital in guaranteeing the safety and security and integrity of structures during building and remodelling jobs. Concrete scanning utilizes innovative innovations such as ground-penetrating radar (GPR) and electromagnetic induction to identify ingrained items, gaps, or various other anomalies within concrete frameworks - RainierGPR Concrete Scanning. By conducting thorough scans before boring, cutting, or coring right into concrete, building and construction groups can prevent accidental damage to important structural elements like rebar, channels, or post-tension wires. This aggressive strategy not just stops costly repairs and task hold-ups however also boosts overall building and construction safety by reducing the risk of architectural failings or collapses due to endangered stability.Furthermore, concrete scanning plays a critical role in making sure conformity with building regulations and guidelines that mandate the protection of existing structural parts during building tasks. By properly mapping out the inner composition of concrete, scanning modern technologies enable building experts to make informed decisions that maintain the structural security and toughness of buildings and infrastructure jobs. Fundamentally, the significance of concrete scanning depends on its capability to protect both the architectural stability and the personnel associated with building undertakings.

Technologies Made Use Of in Concrete Scanning

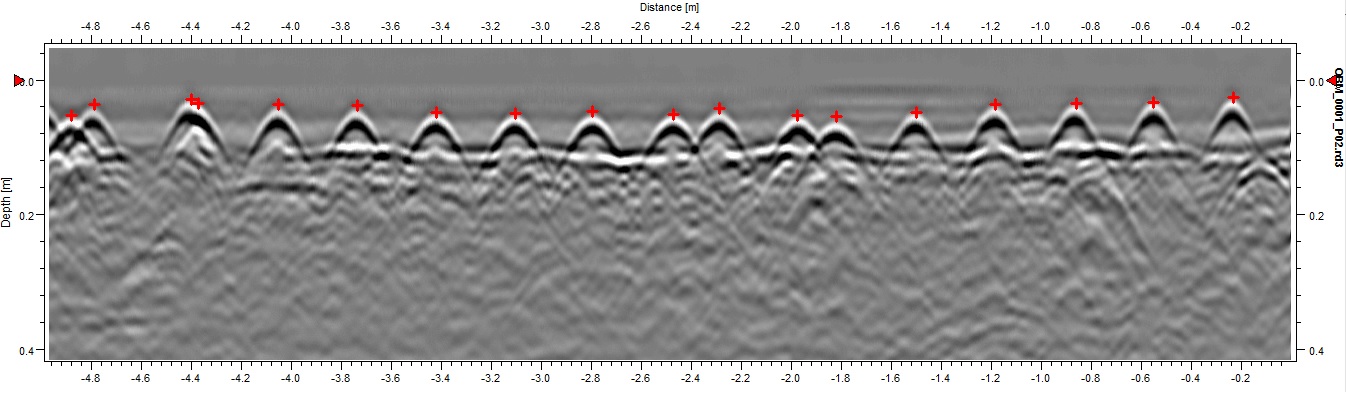

Concrete scanning counts on sophisticated modern technologies such as ground-penetrating radar (GPR) and electro-magnetic induction to precisely spot ingrained items and anomalies within concrete structures. Ground-penetrating radar runs by producing high-frequency electromagnetic waves right into the concrete. When these waves encounter different materials or spaces within the concrete, they bounce back to the surface area, allowing the GPR system to produce a thorough subsurface image. This modern technology is particularly effective in finding rebar, post-tension cords, channels, and various other things installed in concrete.Electromagnetic induction, on the other hand, functions by creating electromagnetic areas around a concrete framework through a transmitter coil. When metal items exist within the concrete, they interrupt these electro-magnetic areas, causing eddy currents to flow with the metal. By determining the adjustments in the magnetic fields with a receiver coil, the system can determine the place of metallic objects in the concrete.

These innovative innovations play a crucial role in non-destructive screening, guaranteeing the safety and honesty of concrete frameworks in numerous sectors.

Applications in Construction Sector

Within the building sector, concrete scanning modern technology locates diverse applications that improve task performance and safety. One key application is the discovery of rebar, post-tension cable televisions, and various other embedded things before exploration or cutting right into concrete structures. By properly mapping out these aspects, building teams can prevent pricey damages, ensure architectural integrity, and stop potential security threats. Furthermore, concrete scanning is used for situating voids, such as air pockets or locations of deterioration within concrete, which can jeopardize the total strength of a structure. By determining these gaps beforehand, building and construction professionals can take needed actions to address them and preserve the sturdiness of the structure. Concrete scanning plays an essential function in top quality control by validating the thickness of concrete covers over reinforcement, guaranteeing conformity with style requirements and standards. In general, the applications of concrete scanning in the building sector add significantly to enhancing job operations, lowering threats, and providing top notch results.

Security Benefits of Concrete Scanning

In the world of building safety, the implementation of concrete scanning technology offers a critical advantage in preemptively identifying possible threats and strengthening architectural integrity. By utilizing advanced scanning techniques such as ground-penetrating radar (GPR) and electro-magnetic induction, construction teams can properly find rebar, post-tension cable televisions, channels, and various other surprise things within concrete structures. This proactive technique significantly lowers the danger of unintentional strikes during exploration, reducing, or coring activities, thus avoiding expensive problems, injuries, and task hold-ups.Moreover, concrete scanning improves employee safety and security by Continued providing real-time info concerning the architectural condition of concrete aspects. This data enables construction professionals to evaluate the honesty of existing frameworks, determine degeneration or flaws, and make notified choices relating to fixing and maintenance treatments. By resolving potential safety issues immediately, concrete scanning adds to developing a safe and secure workplace and alleviating the possibility of structural failings or mishaps on building and construction websites. Inevitably, the safety benefits of concrete scanning not only safeguard lives and assets but additionally promote sector criteria for high quality and reliability.

Future Patterns in Concrete Scanning

Emerging advancements in scanning innovation are poised to transform the area of concrete examination and analysis. One major trend that is obtaining grip is the integration of man-made knowledge (AI) and artificial intelligence formulas into concrete scanning tools. By using the power of AI, these systems can assess vast quantities of data accumulated during scanning processes to offer more thorough and accurate insights into the problem of concrete frameworks. This can aid in discovering surprise defects, anticipating possible structural failings, and also advising upkeep strategies.An additional considerable pattern is the advancement of more user-friendly and portable scanning helpful resources devices. Miniaturization of scanning equipment permits less complicated access to restricted rooms and remote places, making assessments a anonymous lot more extensive and reliable. Furthermore, improvements in cordless interaction modern technologies make it possible for real-time data transfer and evaluation, promoting quicker decision-making procedures.

Moreover, there is a growing concentrate on sustainability in concrete scanning modern technologies - RainierGPR Concrete Scanning. Makers are progressively including eco-friendly products and energy-efficient functions right into their gadgets to decrease environmental impact. These future fads are readied to boost the effectiveness, precision, and sustainability of concrete scanning techniques, forming the market's future landscape

Final Thought

In final thought, concrete scanning plays a critical duty in the construction market by ensuring the safety and security and efficiency of numerous tasks. As technology advances, the future of concrete scanning holds promising advancements for enhancing building and construction procedures.

Report this wiki page